The Advanced Combustion Diagnostics group conducts in-depth research across thermodynamics, fluid dynamics, combustion, heat, and mass transfer. Our work involves developing innovative research methodologies to examine precisely controlled conditions directly applicable to real-world settings like engines, gas turbines, furnaces, and fire scenarios. Importantly, we focus on translating our findings into the real world through detailed techno-economical analysis to guide policy makers, industry stakeholders, and investors.

Apply for research position (Google Form)

Our research activities encompass several key areas, including:

- Fundamental understanding of energy conversion and reacting flows: We delve into the intricacies of energy conversion and reacting flows at a fundamental level. By leveraging advanced diagnostic tools, we optimize engine design, fuel formulation, and operational strategies. Our goal is to enhance operational efficiency while minimizing trade-offs related to stability, emissions, and cost.

- Techno-economic analysis: We conduct comprehensive techno-economic analyses. These assessments quantitatively evaluate the impact of design choices, operational strategies, and technological changes on the system. The resulting insights inform informed decision-making regarding proposed solutions.

- Evacuation modeling and fire risk reduction: We drive changes in existing evacuation modeling approaches and introduce novel crowd sensing technologies. These innovations directly contribute to reducing fire-related risks and improving emergency response procedures.

Current HDR Projects (Click to read)

Current UG Projects (Click to read)

Completed Projects

|

|

Capacity

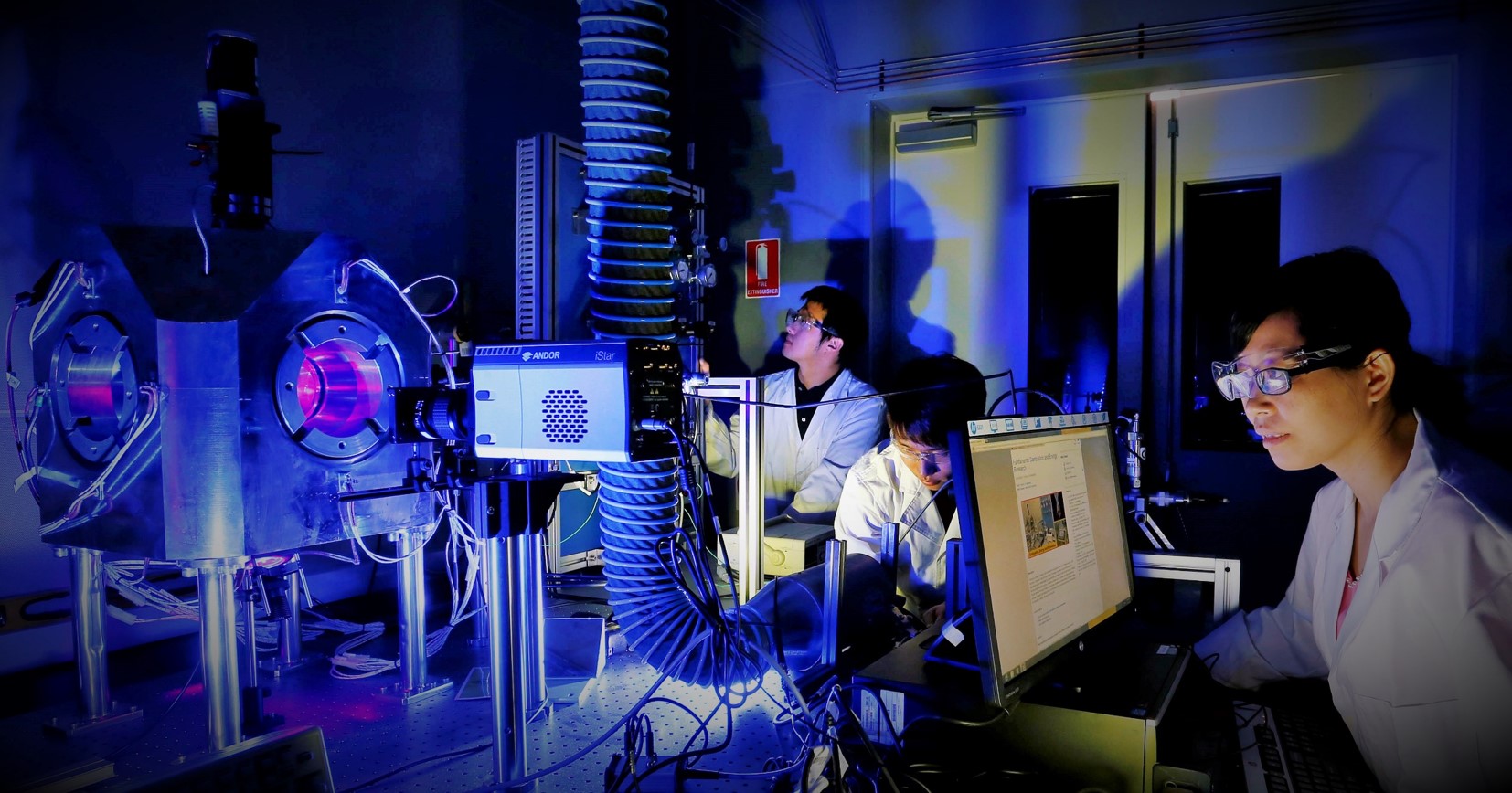

High pressure and temperature constant volume combustion chamber (CVCC)

The chamber is a preburn type that is similar to the facilities at Sandia National Laboratory and other global institutes. The CVCC has a cubical combustion chamber, measuring 100 mm on each side. The CVCC has six window ports and eight access ports for instrumentation and valves and is therefore highly configurable to suit diagnostic needs. Sapphire windows provide optical access to the combustion chamber from four sides, and the fuel injector can be mounted on any of the ports. The high pressure (up to 8MPa) and temperature (up to 1200K) condition within the chamber is generated by spark-igniting a premixed-charged combustible gas mixture that consists of acetylene, hydrogen, oxygen and nitrogen. The fuel is injected into the chamber's centre when the targeted thermodynamic condition is reached after a cool-down period. In the CVCC, the optical windows are flat, the ambient temperature, pressure and composition (from 0 to 21% oxygen) conditions are highly-controlled, and minimal flow is induced. All these create an ideal environment for advanced optical and laser diagnostics.

High-power Nd:YAG pulsed laser

The high‐power Nd:YAG laser (Quantel Brilliant B, Q-smart 450) is capable of delivering a pulse energy of 450 mJ at 1064 nm and 10 Hz. The Nd:YAG laser is coupled with automatic second and third harmonic generator phase matching to produce beam output with wavelength of 355, 532 and 1064 nm, and is capable of operating up to a repetition rate of 20 Hz.

UV-enhanced, intensified CCD camera

The intensified CCD camera (Andor iStar ) is capable of capturing images in the ultraviolet-visible region (200-700 nm) at an image resolution of 1024 x 1024 pixels. The camera has a peak quantum efficiency of 25% in the UV region and is capable of operating at a minimum gate width of 100 ns.

High-speed CMOS color camera

The high-speed camera (Photron SA5) is capable of achieving a maximum frame rate of 1.5 mega frames per second with sub-microsecond exposure. The camera is equipped with a CMOS sensor with a 20 micro meter pixel, that can deliver an ISO light sensitivity of 1,000 and is used to observe combustion events through the optical access windows of the chamber.

Experimental diagnostic capabilities

There are many different diagnostics that can be and have been applied to the combustion vessel. A detailed description of these measurement techniques is provided below:

Associate Professor Shaun Chan

Contact: qing.chan@unsw.edu.au

Webpage: https://research.unsw.edu.au/people/dr-shaun-chan

| HDR candidates | |||

|

Ms Rachel Li |

Mr Yijun Lin |

Mr Kirtan Aryal |

Mr Sensen Xing |

|

Evaluating the techno-economic feasibility of hydrogen engines for stationary power generation and assessing the economic burden of engine pollutants |

Novel ignition approaches for improved hydrogen ignition |

Methanol compression ignition |

Advanced fire evacuation modeling |

|

Education: Present: MPhil (Mechanical Engineering), UNSW Sydney, Australia 2021–2022: Master of Engineering Science (Mechanical), UNSW Sydney, Australia 2015–2020:Bachelor of Aerospace Engineering (Honours Class 2 Division 1), UNSW Sydney, Australia Bachelor of Computer Science (Distinction), UNSW Sydney, Australia |

Education: Present: Advanced Masters (Mechanical Engineering), UNSW Sydney, Australia 2019-2023: Bachelor of Aerospace Engineering, UNSW Sydney, Australia |

Education: Present: Advanced Masters (Mechanical Engineering), UNSW Sydney, Australia 2021: Master of Mechanical Engineering from University of Wollongong, Australia 2013-2017: Bachelor of Mechanical Engineering (Honours Class 1), Dayananda Sagar College of Engineering, Bangalore |

Education: Present: PhD (Mechanical Engineering), UNSW Australia 2013-2017: Bachelor of Mechanical Engineering, Jiangsu University, China |

| HDR graduates | |||

| Dr Patrick Rorimpandey | |||

| Hydrogen-diesel dual-fuel combustion in compression-ignition conditions | |||

| 2024: PhD in Mechanical Engineering, UNSW Sydney, Australia | |||

|

Mr Bob Wan |

Dr Paul Yip |

Dr Mark Zhai |

Mr Sensen Xing |

|

Methane-hydrogen compression ignition |

Hydrogen jet combustion in engine-relevant conditions |

Characterisation of ignition, combustion and flame stabilisation for gasoline-like fuels under compression-ignition conditions |

Study of ignition and combustion characteristics of consecutive injections with iso-Octane and n-Heptane as fuels |

|

2024: Advance Master in Mechanical Engineering, UNSW Sydney, Australia |

2022: PhD in Mechanical Engineering, UNSW Sydney, Australia |

2021: PhD in Mechanical Engineering, UNSW Sydney, Australia |

2020: Advanced Master in Mechanical Engineering, UNSW Sydney, Australia |

| Dr Cheng Wang | Dr Islam Md Rizwanul Fattah | Mr Michael Ming | |

|

Development of compartment fire External irradiation effect on the growth and evolution of in-flame soot species |

Flame-wall interaction in diesel engine environments | Combustion characterization of bio-fuels at high temperature and pressure environments | |

|

2020: Phd in Mechanical Engineering, UNSW Sydney, Australia 2016: Advanced Master in Mechanical Engineering, UNSW Sydney, Australia |

2018: PhD in Mechanical Engineering, UNSW Sydney, Australia | 2018: Advanced Master in Mechanical Engineering, UNSW Sydney, Australia |

Enquiries for Ph.D. or M.E. Positions

We are always in search of capable and self-motivated individuals for PhD/ME students. We have experience in assisting local and international students to apply for research scholarships (Australian Postgraduate Award APA, Chinese Scholarship Council CSC, Science without Borders) to undertake a higher degree by research at UNSW. The group also offers full and top-up scholarships to Ph.D. students of exceptional research potential. For enquiries on available positions, please send your resume to A/Prof Shaun Chan (qing.chan@unsw.edu.au).