The novel and recycled refractories developed will lead to reductions in waste generation through reduced wear, resulting in significant economic and environmental benefits. Optimising the characteristics of these refractories will result in longer refractory life, reduced downtime, and increased product quality. These advances will result in significant advantages for the steel industry.

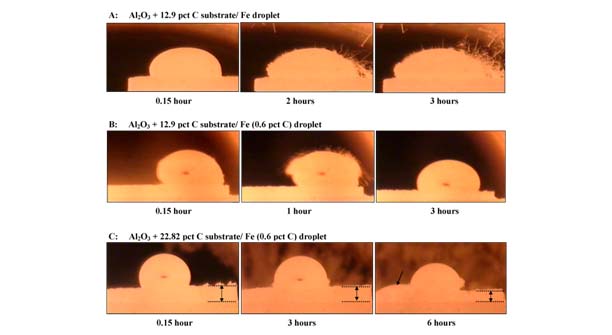

Image description: Video images of molten steel droplets for three configurations: A: (Al2O3 + 12.9 pct C) / Fe; B: (Al2O3 + 12.9 pct C)/ Fe (0.6 pct C)); and C: (Al2O3 + 22.82 pct C)/ Fe (0.6 pct C). Various times indicated in this figure represent reaction times at 1823K.